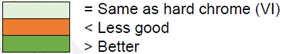

Le tableau suivant montre les propriétés des différentes alternatives comparées au chrome dur (à base de CrVI) comme référence. Ce tableau peut être utilisé pour sélectionner un revêtement ou un traitement alternatif. La résistance élevée à l'usure est souvent la propriété la plus importante du chrome dur dans une application donnée, mais de nombreuses autres propriétés du chrome dur jouent également un rôle : résistance à la corrosion, résistance aux chocs, qualité et finition de la surface, épaisseur de la couche, capacité à recouvrir des substrats de tailles et de formes très différentes, etc.

|

Characteristic

|

Electrolytic plating

|

Electroless plating

|

Vacuum deposition

|

Thermochemical

|

Thermal spraying

|

Hardfacing

|

|

Cr III

|

Ni

|

Ni alloys

|

NiP

|

NiB

|

PVD

|

CVD

|

QPQ

|

HVOF

|

PTA

|

|

Thickness (µm)

|

0,5-100

|

10 - 50

|

10 - 50

|

10 - 50

|

10 - 50

|

1 - 10

|

5 - 50

|

/

|

100 - 2000

|

500 - 10 000

|

|

Wear resistance

|

|

|

|

|

|

|

|

|

|

|

|

Corrosion resistance

|

|

|

|

|

|

|

|

|

|

|

|

Impact resistance

|

|

|

|

|

|

|

|

|

|

|

|

Surface quality

|

|

|

|

|

|

|

|

|

|

|

|

Complex geometry

|

|

|

|

|

|

|

|

|

|

|

|

Temperature sensitive alloys

|

|

|

|

|

|

|

|

|

|

|

|

Large parts

|

|

|

|

|

|

|

|

|

|

|

|

Small parts

|

|

|

|

|

|

|

|

|

|

|

|

Anti-stick

|

|

|

|

|

|

|

|

|

|

|

|

Repair

|

|

|

|

|

|

|

|

|

|

|

|

Productivity

|

|

|

|

|

|

|

|

|

|

|

|

Environment

|

|

|

|

|

|

|

|

|

|

|

|

Caractéristiques

|

Dépôt électrolytique

|

Dépôt chimique

|

Dépôts sous vide

|

Thermo-chimique

|

Pulvérisation thermique

|

Acier dur

|

|

CrIII

|

Ni

|

Ni alloys

|

Ni

|

NiB

|

PVD

|

CVD

|

QPQ

|

HVOF

|

PTA

|

|

Epaisseur (µm)

|

0,5 -100

|

10 - 50

|

10 - 50

|

10 - 50

|

10 - 50

|

1 10

|

5 - 50

|

/

|

100 - 2000

|

500 - 10000

|

|

Résistance à l'usure

|

=

|

<

|

=

|

<

|

=

|

>

|

>

|

=

|

>

|

>

|

|

Résistance à la corrosion

|

<

|

>

|

>

|

>

|

>

|

<

|

=

|

=

|

=

|

>

|

|

Résistance aux chocs

|

<

|

=

|

=

|

<

|

<

|

=

|

>

|

>

|

<

|

>

|

|

Qualité de la surface

|

=

|

>

|

=

|

=

|

=

|

>

|

<

|

>

|

<

|

<

|

|

Géométrie complexe

|

=

|

=

|

=

|

>

|

>

|

<

|

>

|

>

|

<

|

<

|

|

Alliages sensibles à la température

|

=

|

=

|

=

|

<

|

<

|

<

|

<

|

<

|

<

|

<

|

|

Grandes pièces

|

=

|

=

|

=

|

<

|

<

|

<

|

<

|

=

|

=

|

=

|

|

Petites pièces

|

=

|

=

|

=

|

>

|

>

|

<

|

<

|

=

|

<

|

<

|

|

Anti-adhérent

|

=

|

<

|

<

|

<

|

<

|

=

|

=

|

>

|

=

|

<

|

|

Réparation

|

<

|

<

|

<

|

<

|

<

|

<

|

<

|

<

|

>

|

>

|

|

Productivité

|

=

|

=

|

=

|

<

|

<

|

<

|

<

|

<

|

<

|

<

|

|

Environnement

|

=

|

=

|

=

|

=

|

=

|

>

|

<

|

<

|

>

|

>

|